Home » Services » List of tests » Uniaxial compression test

Uniaxial compression test: how long can a rock resist?

The Uniaxial Compression Test, or also uniaxial test or simply uniaxial test, is a test that allows to characterize the strength of a rock and is standardized according to the ASTM-D7012 standard.

The uniaxial compression test complies with test methods C and D of the ASTM-D7012 standard; it can in fact be conducted in two ways:

- Single-axis test method C: with this method the compressive strength of the rock is measured, without investigating its deformation;

- Monoaxial Test Method D: in this case the uniaxial test involves the determination of the elastic modules and therefore investigates both the compressive strength and the deformation mode, giving rise to the characteristic stress-strain curve (stress vs. strain).

The specimen to be tested in a uniaxial compression test must have a length / width ratio of 2: 1 to 2.5: 1 and is commonly a cylinder. The water content of the sample for uniaxial tests must be as close as possible to the sampling conditions.

Apparatus for carrying out single-axis tests, present at the Tonon Rocks and Research Laboratory: (1) plate system operated by an automatic pneumatic system for load application; (2) control unit and setting of the test parameters; (3) specimen ready for the Uniaxial Test – Method C (Source: Laboratorio Rocce e Ricerca Tonon, srl).

Monoaxial compression test according to method C: detail of the specimen in its housing. When performing a uniaxial test without measuring the deformation modules, the set-up does not require the use of systems for measuring axial and radial deformation (Source: Laboratorio Rocce e Ricerca Tonon, srl).

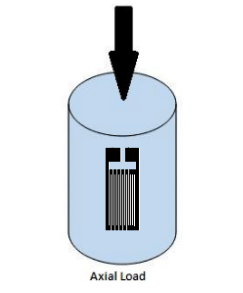

A uniaxial compression test conducted with method D requires the system to be equipped with axial and lateral strain gauges. Laboratory Rocks and Research Tonon uses strain gauges similar to the one shown in the figure, applied along the axis and circumference of the specimen (Source: JohnHiatt, Siemens Experimenter).

To perform a uniaxial test, the load must be applied continuously, generally at a variable speed between 0.5 and 1 MPa / s, in order to generate the failure of the specimen in a time between 2 and 15 minutes. During the uniaxial test, the following must be recorded continuously:

1. The applied load in kN – rounded to the second decimal place;

2. The corresponding pressure (stress) in MPa – rounded to the first decimal place;

3. The maximum load (kN).

At the end of the test, the uniaxial compressive strength of the rock (MPa) is finally calculated, i.e. the ratio between the breaking load (N) and the area of application of the same (mm2).

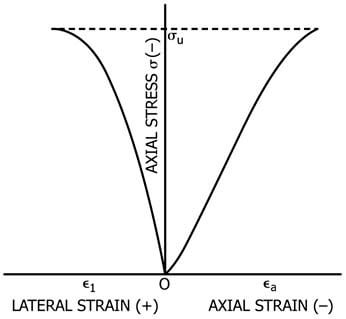

The axial strain is calculated as the ratio between the recorded length variation and the initial length; the same is true for lateral deformation, where the ratio will be between the variation in diameter and the initial diameter.

Once these values are known, it is possible to obtain the stress vs. strain of the uniaxial test, which should be plotted for the axial and lateral component of the strain.

Representative graph of the deformation behavior of a rock subjected to uniaxial compression. This graph, known as the stress-strain curve, is generated only with the Uniaxial Compression Test – Method D (Source: ASTM D7012).

Once the curve has been obtained, it is possible to obtain the Young’s Modulus and Poisson’s Ratio values using different approaches; these values characterize the behavior of a rock from the point of view of its monoaxial compressive strength, that is, to the application of the load. It is important to reiterate that the more anisotropic the rock specimen is, the less representative the elastic modules obtained from the uniaxial tests will be.

The most used ways to calculate the elastic modulus (Young’s Modulus and Poisson’s Ratio) starting from the stress vs. deformation (Source: ASTM D7012).